The many benefits of horizontal directional drilling in today's market

In the past, installing pipes and utilities required surface digging. This approach, often known as "open cut," is quite disruptive and has several drawbacks. The open-cut method removes vegetation from the surface, harming already-existing facilities like roads and streets, creating traffic congestion, and increasing the cost of infrastructure restoration.

Modern trenchless methods, however, are far superior to the open-cut approach. These include horizontal directional drilling, pipe bursting, and slip lining (HDD). The greatest alternative for installing, repairing, maintaining, or replacing pipes is Horizontal Directional Drilling.

Horizontal Directional Drilling: What Is It?

The trenchless technology known as horizontal directional drilling (HDD), sometimes known as directional boring, is used to establish or replace sewer, water, and gas lines.

What Is the Process of Horizontal Directional Drilling?

Drilling the pilot hole, widening the drilling hole, and hauling the production pipe are the three fundamental steps in the horizontal directional drilling process. A pilot hole is first drilled by the directional driller. They drill a hole with a small diameter using a drill bit and pipe assembly.

The drill bit is assisted in cutting through the rock and soil by drilling fluid. It cools and lubricates the drill bit. It returns cuttings from the hole to the surface as well.

Horizontal Directional Drilling Applications

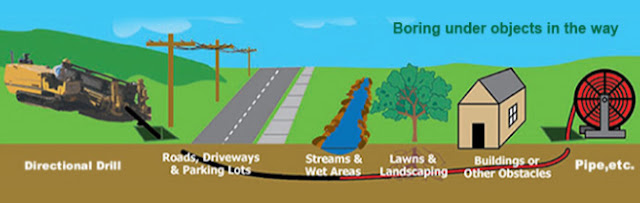

The most typical method of installing a traditional pipeline entails digging a trench and inserting a pipe into it. However, it isn't always feasible to dig a surface trench. Horizontal directional drilling may be a better choice if the pipeline needs to pass underneath an obstruction like a road or river.

Several different kinds of subsurface infrastructure can be installed using Horizontal Directional Drilling. Typical applications comprise:

Pipelines for sewage and water

Pipelines for natural gas and oil

Electric wires

Cables for telecommunications and fiber optics

The largest portion of the worldwide HDD market is made up of telecom installations.

Horizontal Directional Drilling (HDD) is a general term for any drilling technique used to minimize the need for surface excavation. There are some reasons why HDD has recently become quite popular.

Let's examine the key factors contributing to its popularity:

1. Less disruption to infrastructure

Utility pipes are laid down using horizontal directional drilling throughout various countries of the world because this method has proven to be quite practical in heavily populated areas. When drilling beneath already-built buildings like highways or bridges, directional boring also reduces expenses.

2. Environmental Advantages

Horizontal directional drilling is one of the most effective methods for putting pipes beneath rivers, wetlands, and waterways over the years, allowing contractors to perform the absolute fewest excavations possible. Drilling may be done across all kinds of terrain without endangering the soil, subsurface water, or ecology thanks to technologies like Horizontal Directional Drilling drill bits and hole openers.

3. It is economical

Horizontal directional drilling is significantly more cost-effective than other drilling techniques, especially when it comes to adding piping, although it requires additional tools. To increase productivity, it's important to choose the appropriate equipment.

It's crucial to keep in mind that Horizontal Directional Drilling PDC bits and reamers are quick, robust, and simple to steer into the proper forms. Thus, a mismatch can have a considerable impact on a bit's or reamer's overall performance. The designs of PDC bits vary widely depending on the quantity, size, and angles of the blades.

When compared to the open-cut method of pipe installation, trenchless technologies like Horizontal Directional Drilling have significant benefits. However, their environmental friendliness is by far its greatest benefit. Quality pipes are still required to finish the job, though.

One of the most reputable PDC drill bit producers in the world is Gridtech. Additionally, we can alter our products to meet your needs. Please feel free to look around the website and ask for a quote right now.

.jpg)

.jpg)

Comments

Post a Comment