What is horizontal directional boring and how does it work

Horizontal directional boring (HDB) is a method of installing underground pipelines and utilities without

disturbing the surface of the ground. The process involves a drill head being inserted into the ground

and then steered in a predetermined path using a control console. This allows for the efficient

installation of pipes, cables and other conduits without the need for digging large trenches or excavating

large areas of land.

HDB is an efficient and cost-effective method of installing underground utilities. The process is non-

invasive, meaning it does not require the destruction of existing vegetation, infrastructure or ground

surfaces. This makes it ideal for projects in densely populated areas or in areas with limited access due

to terrain.

Required Gear for HDD

The boring apparatus is the primary component of an HDD arrangement. Boring poles are added to each

fragment in turn as the penetrating head advances through the ground. A boring head joined to the

front of the drill string slices through the dirt and drops the cuttings into the passage. There are different

penetrating heads intended for various ground conditions.

Most HDD projects depend on a boring mud framework. This bentonite combination seals the passage

walls and forestalls subsidence (sinking or settling). It likewise does the cuttings of the passage and gives

grease and cooling to the penetrating head.

Stage 1

Stage 1 in an Horizontal directional boring project is the penetrating of a pilot bore. The reason for the pilot bore is to guarantee

that the line follows the plan direction. The pilot bore is generally little and more straightforward to

penetrate, permitting project workers to find any issues with the ground condition so they are

completely ready to maneuver the line into position.

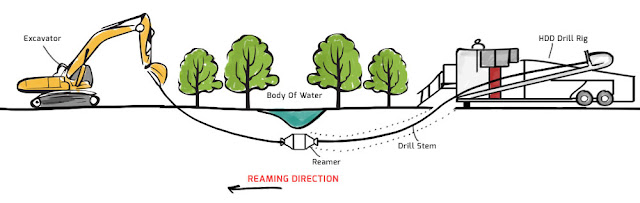

Stage 2

Stage 2 is to ream the pilot bore and increment the drag size to fit the item pipe. Reaming may take a

few passes, every one greater than the last until the last size is reached. A reaming device fits onto the

finish of the drill string instead of the boring head. Boring mud assumes a critical part in eliminating the

cuttings from the passage and keeping up with the strength of the walls.

Stage 3

Stage 3 of HDD is the laying of the line. A pulling head and turn supplant the boring head at the front of

the drill string. Funneling is much of the time maneuvered once more into the drag from the objective

site, which takes a lot of power and puts huge strains on the line. One of the issues that can happen

here is a stuck line, where the line will not drop any further down the passage.

HDD Restrictions

The vast majority of the disservices of HDD are connected with the utilization of boring mud and ground

conditions. Some ground conditions have free rock or soil, which makes it challenging to seal the drag.

Under these circumstances, it could be smarter to introduce packaging followed by the item pipe.

Boring mud can likewise burst through the passage into the encompassing soil due to high strain or

erroneous penetrating mud creation. This disappointment can cause subsidence and ecological harm,

prompting defers in the task while correcting what is going on.

Advantages of HDD

HDD establishments don't need passage and leave pits. The funneling is introduced from the surface at a

point into the ground. This entrance implies no development of entry and leaves pits, however, it might

in any case require an enormous impression for the run-up of line into the drag.

A huge advantage of HDD is the capacity to follow bent directions. More seasoned trenchless

development strategies like drill drilling can follow a straight line. Bent directions permit funneling to

plunge underneath a waterway, rail or street and afterward rise again on the opposite side. There are no

underground elbows to stress over and no right-point changes in the stream way. The improvement of

HDPE channeling has likewise added to this advantage on the grounds that the funneling is sufficiently

adaptable to follow a bent direction, dissimilar to steel channeling.

Conclusion

The process begins by drilling a pilot hole along the planned route of the utility. The drill head is then

steered through the pilot hole and gradually enlarged until the desired width is achieved. The walls of

the borehole are then reinforced with a steel casing to protect the integrity of the borehole and the

utility. The utility is then pulled through the borehole and connected to the existing infrastructure.

HDB is commonly used for the installation of telecom and utility cables, sewage lines and water

pipelines. The process is also used for directional drilling, a process of drilling a curved path through the

ground in order to reach a desired location. This is often used for the installation of gas pipelines in

areas where it would be difficult to dig a straight trench.

HDB is an efficient and cost-effective method of installing underground utilities without disrupting

existing vegetation or infrastructure. The process is quick, minimizes surface disruption and can be used

in areas where digging large trenches or excavating large areas of land would be difficult.

.jpg)

Comments

Post a Comment