The Advantages of Underground Boring with Directional Drilling

Are you seeking innovative, cost-effective answers to your everyday problems? Or would you want a rapid and simple installation of your underground utilities? All of your needs can be met by services for underground drilling.

Thanks to advancements in boring technology, installing utilities and other underground digging operations have never been simpler. This is especially true for the construction industry.

In this article, we'll define underground boring services and discuss their benefits for your next project. The article will list several benefits that you may expect from using the boring services.

How do boring services work?

The term "underground boring services" is frequently used to describe the method known as horizontal directional drilling. It is a method of drilling underground that does not require trenches to lay utilities and pipelines.

Instead of digging trenches on the ground, you can insert your pipelines and utilities through deep boreholes thanks to the HDD. When trenching and excavation are not the best options, this technique is employed. Users can complete their drilling operation in any type of soil with this drilling technique.

Before starting the boring process, it is essential to determine the soil type and take into account any potential impediments. The engineer or worker will evaluate the depth and angle at which the borehole should be bored as they are drilling.

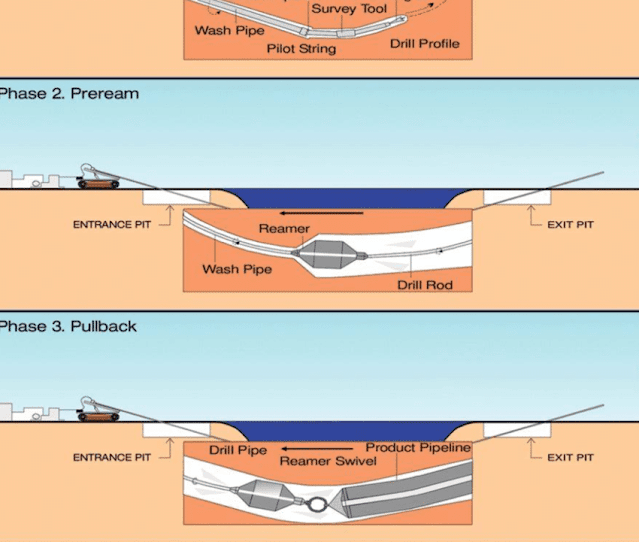

Drilling an opening into the previously selected path is the first step of the process. The machine will widen the hole to the proper diameter as it drills deeper into the ground once boring has begun.

The required utility, such as electrical wire or a pipeline, is lowered into the ground once the hole has been drilled. It is lowered using a special pull-out mechanism connected to the boring machinery. Once the worker has fitted the utility, the borehole is sealed off and the drilling area is put back to normal.

Why is it advantageous?

One benefit of using HDD to build utilities and pipes is that it has less of an impact on the environment than traditional open-cut methods. During an open-cut excavation, digging a trench or a hole can damage local vegetation, alter the surrounding landscape, and cause soil erosion. Additionally, it might contaminate water sources and animals' habitats, which would be bad for the ecosystem.

In contrast, horizontal directional drilling minimises disruption to the surface during pipe building. Using a guided drilling machine, the process entails drilling a very tiny pilot hole from the entry site to the exit point. The drill head is steered underground along the intended path, which can be changed in real-time to avoid impediments like trees.

When installing pipelines, horizontal directional drilling performs better than open-cut construction. The procedure moves along more swiftly, easily, and labor-effectively. When several pipelines are constructed using underground boring services in a single borehole, no additional excavation sites are needed. The technique results in less pollution from noise, dust, and debris.

Additionally, HDD makes it possible to build pipelines in difficult terrains where conventional open-cut techniques are impractical, such as rocky soil, marshes, and urban areas. Additionally, the therapy lessens the need for additional maintenance and rehabilitation procedures, saving both time and money.

The cost of using underground boring services is lower than using more conventional open-cut pipe installation methods. The process requires less excavation and material input, which lowers manpower and equipment expenses. Additionally, Horizontal Directional Drilling enables the installation of pipes in challenging locations, obviating the need for costly maintenance and restoration initiatives.

Additionally, HDD lessens the possibility of pipeline leaks and damage, which could be expensive to fix, endanger public safety, and have a bad effect on the environment. Additionally, the method requires less maintenance, which lowers long-term expenditures even more.

Final Reflections

Compared to conventional excavation techniques, underground boring services are more inexpensive, less intrusive, and quicker to implement. They are a well-liked option for many construction projects because of their adjustability and environmental friendliness.

Choose a reliable and competent contractor that can offer the knowledge and technology required for a successful installation if you're thinking about using underground boring services for your upcoming project. Utilising HDD can help businesses become more productive, reduce expenses, enhance safety, and have less of an impact on the environment. Therefore, HDD should be considered a viable choice for pipeline installation projects.

.jpg)

Comments

Post a Comment