What Is the Cost-Saving Strategies for HDD Contractors?

Are You Maximizing Savings? Explore Cost-Saving Strategies for HDD Contractors!

In the competitive field of Horizontal Directional Drilling (HDD), managing costs while maintaining high-quality outcomes is crucial. For HDD contractors, balancing these elements can be challenging but not impossible.

By adopting effective cost-saving strategies, contractors can enhance their profitability and ensure sustainable business growth.

Today, this blog post will delve into various strategies HDD contractors can employ to save costs without compromising on quality and efficiency.

Understanding the Basics of HDD

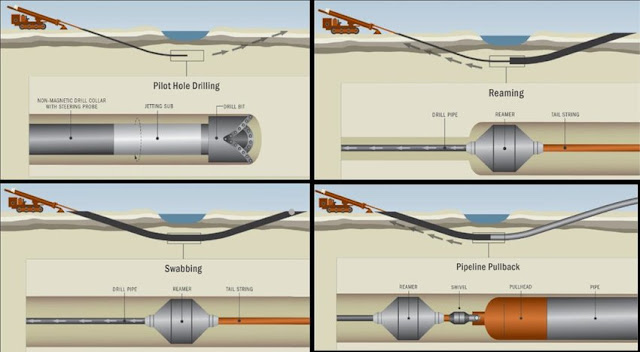

Before diving into cost-saving strategies, let’s briefly understand what HDD entails. Horizontal Directional Drilling is a trenchless method of installing underground pipes, conduits, and cables with minimal surface disruption. It is widely used for utility installations, telecommunications, and oil and gas pipelines. The precision and efficiency of HDD make it a preferred choice for many contractors, but the costs can quickly add up without careful management.

1. Invest in Advanced Technology

One of the most effective ways to save costs is by investing in advanced drilling technology. Modern HDD equipment comes with enhanced features such as real-time monitoring, automated controls, and improved accuracy, which can significantly reduce drilling time and operational costs. Here’s why investing in technology pays off:

Increased Efficiency: Advanced equipment can complete tasks faster, reducing labor costs.

Reduced Downtime: Modern machinery is often more reliable and less prone to breakdowns.

Enhanced Precision: Accurate drilling minimizes the need for rework, saving both time and materials.

2. Optimize Equipment Utilization

Efficient utilization of equipment is crucial for cost savings strategies for HDD Contrators. This involves ensuring that all machinery is operating at its optimal capacity and minimizing idle times. Strategies to optimize equipment utilization include:

Regular Maintenance: Keeping equipment in good condition prevents unexpected breakdowns and extends its lifespan.

Training Operators: Well-trained HDD Contractors can maximize the efficiency of the equipment, ensuring optimal performance.

Equipment Scheduling: Proper scheduling ensures that equipment is available when needed, reducing idle times and rental costs.

3. Implement Effective Project Planning

Thorough project planning can prevent costly delays and overruns. Effective planning involves:

Detailed Site Surveys: Understanding the site conditions beforehand of HDD contractors helps in planning the appropriate drilling approach.

Accurate Cost Estimation: Detailed cost estimation helps in budgeting accurately and avoiding unexpected expenses.

Risk Management: Identifying potential risks and having mitigation strategies in place can prevent costly disruptions.

4. Leverage Bulk Purchasing

Buying materials in bulk can lead to significant cost savings. HDD Contractors can negotiate better rates and reduce per-unit costs by purchasing larger quantities. Bulk purchasing also ensures a steady supply of materials, preventing project delays due to material shortages.

5. Embrace Reusable Materials

Using reusable or recyclable materials can reduce material costs and contribute to sustainability. For example:

Recycling Drilling Fluid: Reusing drilling fluids after proper cleaning can significantly cut down on fluid costs.

Reusing Drill Pipes: Investing in durable drill pipes that can be reused across multiple projects reduces the need for frequent replacements.

6. Streamline Logistics and Supply Chain

Efficient logistics and supply chain management can lower transportation and storage costs. Strategies include:

Local Sourcing: Procuring materials locally reduces transportation costs and supports the local economy.

Just-in-Time Delivery: Scheduling deliveries to coincide with project phases minimizes storage costs and reduces the risk of material damage.

Collaborating with Reliable Suppliers: Building strong relationships with suppliers can lead to better pricing and reliable supply chains.

7. Adopt Energy-Efficient Practices

Energy expenses often make up a considerable portion of operational costs. Embracing energy-efficient practices has the potential to result in significant cost savings:

Use Energy-Efficient Equipment: Opting for equipment with lower energy consumption can reduce fuel costs.

Implement Energy-Saving Measures: Simple measures like regular equipment maintenance, proper insulation, and using energy-efficient lighting can cut down on energy expenses.

8. Optimize Labor Costs

Labor is a major cost component in HDD projects. Optimizing labor costs without compromising quality involves:

Efficient Workforce Management: Ensuring that the right number of HDD contractors or workers are assigned to each task prevents overstaffing and underutilization.

Training and Skill Development: Investing in training enhances worker productivity and reduces the likelihood of costly mistakes.

Outsourcing Specialized Tasks: For tasks that require specialized skills, outsourcing can be more cost-effective than maintaining a full-time specialized workforce.

9. Enhance Communication and Coordination

Effective communication and coordination among project stakeholders can prevent misunderstandings and errors, leading to cost savings. This can be achieved through:

Regular Meetings: Frequent meetings ensure that all stakeholders are aligned and aware of project progress and issues.

Clear Documentation: Maintaining clear and detailed documentation prevents miscommunication and provides a reference for resolving disputes.

Utilizing Collaboration Tools: Digital collaboration tools facilitate real-time communication and information sharing, improving project coordination.

10. Monitor and Analyze Project Performance

Continuous monitoring and analysis of project performance help in identifying areas for improvement and implementing corrective actions promptly. Key practices include:

Performance Metrics: Establishing key performance indicators (KPIs) to track progress and identify inefficiencies.

Regular Audits: Conducting regular audits to ensure compliance with project plans and standards.

Feedback Mechanisms: Implementing feedback mechanisms to gather insights from workers and stakeholders for continuous improvement.

11. Adopt Sustainable Practices

Sustainable practices not only benefit the environment but can also lead to cost savings. Strategies include:

Minimizing Waste: Implementing waste reduction measures can lower disposal costs.

Using Eco-Friendly Materials: Opting for sustainable materials can reduce environmental impact and may qualify for tax incentives or grants.

Energy Recovery: Implementing systems to recover and reuse energy from drilling processes can reduce overall energy costs.

12. Utilize Project Management Software

Project management software can streamline operations, enhance efficiency, and reduce costs. Benefits include:

Improved Scheduling: Automated scheduling tools ensure that tasks are planned efficiently, reducing delays.

Resource Management: Effective resource management tools help in optimizing the use of materials, equipment, and labor.

Real-Time Tracking: Real-time tracking of project progress enables prompt identification and resolution of issues.

13. Negotiate Favorable Contracts

Negotiating favorable contracts with clients and suppliers can result in cost savings for HDD contractors. Tips for effective negotiation include:

Clear Scope Definition: Clearly defining the project scope prevents scope creep and additional costs.

Flexible Terms: Negotiating flexible terms can provide more control over project costs and timelines.

Long-Term Agreements: Establishing long-term agreements with suppliers can lead to better pricing and consistent supply.

14. Focus on Quality Assurance

Investing in quality assurance prevents costly rework and project delays. Key practices include:

Quality Control Procedures: Implementing stringent quality control procedures ensures that work is completed to the required standards.

Regular Inspections: Conducting regular inspections helps in identifying and addressing issues early.

Training in Quality Standards: Providing training to HDD contractors on quality standards ensures that all workers are aware of the expected quality levels.

Conclusion

Cost-saving strategies for HDD contractors encompass a broad range of practices, from investing in advanced technology and optimizing equipment utilization to implementing effective project planning and embracing sustainable practices. By adopting these strategies, HDD contractors can enhance their efficiency, reduce operational costs, and improve their competitive edge in the market.

As the HDD industry continues to evolve, staying updated with the latest trends and innovations is crucial for maintaining cost-efficiency and achieving long-term success. By continuously refining their cost-saving strategies, HDD contractors can ensure they are well-positioned to meet the demands of future projects and deliver exceptional value to their clients.

Comments

Post a Comment